Biomedical Application: The development of numerous medical devices, medications, and biomaterials have made great use of manufacturing methods. New technologies that have assisted in the advancement of biomedical science have been created as a result of the utilization of manufacturing techniques. In this blog, we will go through some of the most important manufacturing procedures in biomedical science.

The creation of medical devices is one of the main uses of manufacturing processes in biomedical science or Biomedical Application. Medical devices refer to instruments, apparatuses, equipment, or implants used in the diagnosis, treatment, or prevention of various illnesses or medical problems. Typically, these devices are constructed from a variety of materials such as composites, metals, ceramics, and polymers. Manufacturing procedures are used to produce medical devices with particular physical, chemical, and mechanical characteristics that satisfy the needs of numerous medical applications.

For instance, the manufacturing technique of injection molding is used to create a variety of medical devices, including needles, catheters, and prosthetic limbs. In injection molding, plastic is melted and injected into a mold where it hardens and adopts the shape of the mold. The final gadget is ideal for mass production, has great strength, and has outstanding dimensional precision.

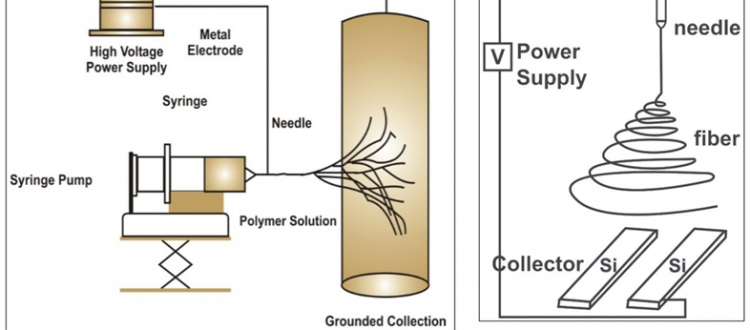

Manufacturing procedures are also utilized to create biomaterials, in addition to drugs and medical devices. Biomaterials are substances that can be utilized to replace or restore different organs and tissues in the human body. These materials should possess mechanical, biocompatibility, and biodegradability traits that are comparable to those of natural tissues. One type of production method used to create biomaterials is electrospinning. Using an electric field, polymer fibers are spun into a non-woven mesh during electrospinning. The high surface area to volume ratio of the produced biomaterial promotes excellent cell adhesion and proliferation.

Pharmaceutical manufacturing is another area of biomedical science where manufacturing techniques are used. Drugs for diverse medical diseases are developed, produced, and distributed as part of the pharmaceutical manufacturing process. Pharmaceuticals having particular qualities, such as stability, solubility, and bioavailability, are created via manufacturing techniques. Compression of tablets is one example of a manufacturing procedure used in medicines. Compressing a powder combination into tablets of various sizes and shapes is known as tablet compression. The resultant tablets have exceptional mechanical strength and can be taken orally.

Tissue-engineered constructions are made using manufacturing procedures as well. Tissue engineering entails the creation of synthetic organs and tissues that can replace or treat diseased or damaged tissues. These structures are often created from biomaterials and cells and are intended to resemble the characteristics of real tissues.

3D printing is an illustration of a production technique used in tissue engineering. To produce a three-dimensional structure, materials are deposited one layer at a time during 3D printing. The resulting tissue-engineered constructions are very structurally sound and can be used to replace or restore a variety of tissues and organs.

In summary, manufacturing techniques have contributed significantly to the development of biomedical science. The utilization of manufacturing techniques has resulted in the creation of numerous medications, biomaterials, and tissue-engineered constructions. Many diseases and medical issues can now be more accurately identified, treated, and prevented.

Written By:

Mr. Yatharth, Student, B.Tech, Mechanical Engineering (Batch 2021-2025), SGT University.

Dr. Atul Babbar, Assistant Professor, Mechanical Engineering Department, SGT University.