Microwave Radiation are a type of electromagnetic radiation that consists of magnetic and electric waves propagating perpendicular to each other. They have wavelengths ranging from 30 cm to 1 mm in air and belong to the frequency range of 300 MHz to 300 GHz on the electromagnetic spectrum. The versatility of microwave frequencies has led to their use in various applications, including food processing, medical procedures, communication systems, industrial heating, and material processing. In India, microwaves are allocated a frequency range of 2.45 GHz, but frequencies ranging from 915 MHz to 18 GHz are utilized for microwave heating furnaces.

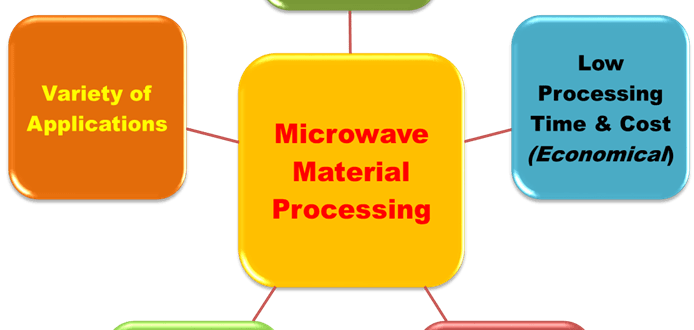

Initially, microwaves were limited to communication systems, such as satellite communications, radar, and television broadcasting. However, in 1945, Percy Spencer, an American physicist, and inventor, discovered the heating effects of microwave radiation and patented the technology for heating purposes, known as the microwave oven. This invention led to further exploration of microwave applications in heating materials, such as vulcanization of rubber, steel making, processing of ceramics and metallic materials, and alternative sources of energy recovery. Figure 1 illustrates the main characteristics of microwave radiation as a heating source during material processing.

The interaction of microwaves, like any other electromagnetic radiation, with the material, is governed by certain properties of electromagnetic radiation, particularly amplitude, both electric and magnetic field components, phase angle, and rate of transfer of energy from one point to another point; that is the ability to propagate through the material. During exposure to microwaves, electric and magnetic properties of the material, such as tangent loss, dielectric constant, and resistivity, also play a decisive role in the interaction of the material with electromagnetic radiation to produce heat in some of them. Based on the response of the materials to microwave irradiation, the materials can be categorized in the following ways:

Transparent materials: The materials with low dielectric loss factor that allow the microwaves to penetrate and transmit through them completely without absorption of any energy component are termed transparent materials or low-loss insulators materials. Materials like alumina (Al2O3), Teflon, glass, thermosetting plastics, and quartz are some examples of this class of materials.

Opaque materials: The materials with a high dielectric loss factor that reflect the microwaves completely, without absorption of any energy component, or allow negligible penetration are termed opaque materials or conductors. In general, all metals are conductors at room temperature and come under this category.

Absorbent materials: Materials with mixed properties in the range from conductors to insulators, absorb microwaves readily and convert this absorbed electromagnetic energy into heat; they are termed absorbent materials or lossy dielectrics. Materials like charcoal and ceramics are some examples of these types of materials.

Mixed absorbers: The advanced materials that have mixed or multi-phase and in which one phase acts as a high-loss insulator and the other as a low-loss insulator are termed mixed absorbers. Some materials are transparent to microwaves such as alumina, glass, and silica, but start absorbing microwaves after being heated to a critical temperature. On the other hand, some materials, such as silicon carbide, absorb microwaves effectively even at ambient temperature. Therefore, in materials that are transparent to microwaves, a microwave-absorbing second phase is added intentionally to absorb microwave energy effectively even at room temperature. Polymer matrix composites and ceramic matrix composites are some examples of these types of materials.

By

Dr. Sandeep Bansal

Assistant Professor

Mechanical Engineering Department

SGT University